Synthetic waxes: Innovation in production

Conventional methods for manufacturing polyolefin waxes, whether polyethylene, oxidized polyethylene, or polypropylene, typically involve the polymerization of ethylene or propylene, resulting in different molecular chains of polyolefin waxes.

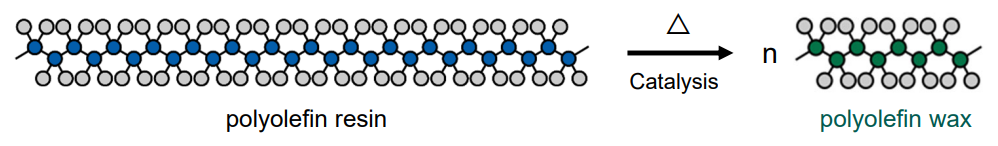

In the MEGH technology approach, our production is differentiated. We don’t start with ethylene; instead, we employ an exclusive process of depolymerization, known as cracking, of PE (polyethylene) and PP (polypropylene) resins. This method allows us to create waxes with highly defined characteristics that are remarkably similar to materials generated through traditional polymerization.

Uncover the revolution of biodegradable polyolefin waxes! Scan the QR code and dive into our exclusive brochure. The future awaits you!

Natural waxes: The essence of nature in our products

At MEGH, we develop a wide range of natural and vegetable-based waxes through our own technology. This includes materials directly extracted from nature, as well as esters with wax properties (SEW technology) obtained through chemical reactions with vegetable and natural raw materials.

Uncover the future of SEW ester waxes in detail! Scan the QR code and access our exclusive brochure right now.

Micronized waxes: The revolution in size and performance

We have developed an innovative production technology based on the depolymerization of polyolefin waxes and the use of natural, renewable, and biodegradable waxes. Thanks to these technologies, MEGH can create a wide variety of micronized waxes with exceptional characteristics.

Emulsions: Water-Based technology

In our product line, which stands out for its natural, renewable, and biodegradable properties, MEGH is proud to present a diverse selection of emulsions that share these exceptional characteristics.

Dispersions

In our renowned product line, known for its natural, renewable, and biodegradable properties, MEGH is pleased to offer a wide variety of dispersions that share these exceptional attributes.